Thick Gears and Carrier Breaks

Car and truck axles come in a variety of gear ratios depending on their application and many aftermarket gear manufacturers extend that range even further with extra high and extra low gear ratios.

The gear ratio in an axle determines how many times the drive shaft needs to spin in order to turn the wheels one rotation. For example, a 3.73 gear ratio requires the drive shaft to spin 3.73 times to turn the tires around once.

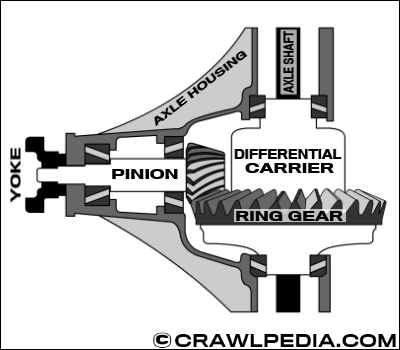

In the diagram below, the drive shaft turns the pinion against the ring gear that is connected to the wheels via the axle shafts. The number of teeth on the pinion and the ring gear are what determine the gear ratio.

The higher a gear ratio is numerically, the more the engine needs to turn to spin the tires. Higher gear ratios work great for trucks that need more torque to get heavy loads moving while numerically lower gears are better for racing and for improving highway gas mileage because the engine can turn slower at higher speeds.

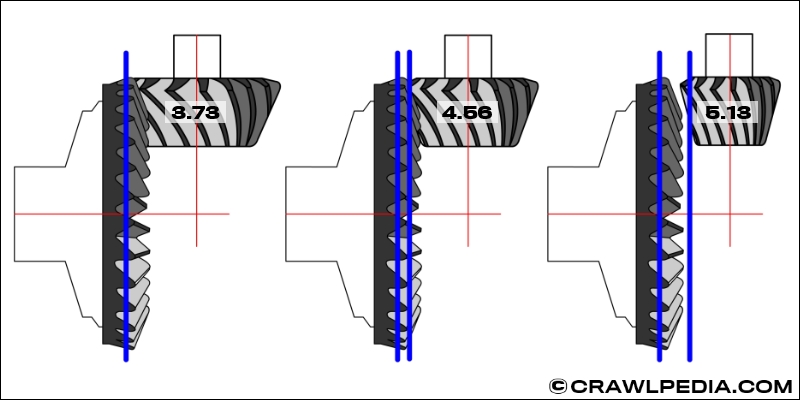

Ring and Pinion Gear Sizes and Alignment

The gear ratio of any axle can be calculated by dividing the number of teeth on the ring gear by the number of teeth on the pinion gear. For example, an axle with 41 ring gear teeth and 11 pinion gear teeth would have a 3.73 gear ratio (41/11 =3.73).

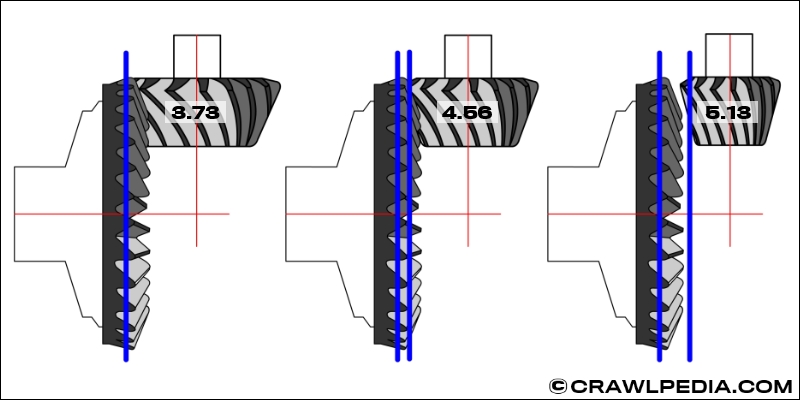

Low gear sets have more teeth on the pinion gear than high ratio gears do and as such the overall diameter of the pinion gear tends to change significantly across the scale of ratios. Ring gears, on the other hand, maintain their size because the teeth are cut on the face of the gear and not along the circumference. As a result, and because axle housings are machined with a fixed position for the pinion and differential carrier that holds the ring gear, a gap is created between the two gears as the gear ratio increases.

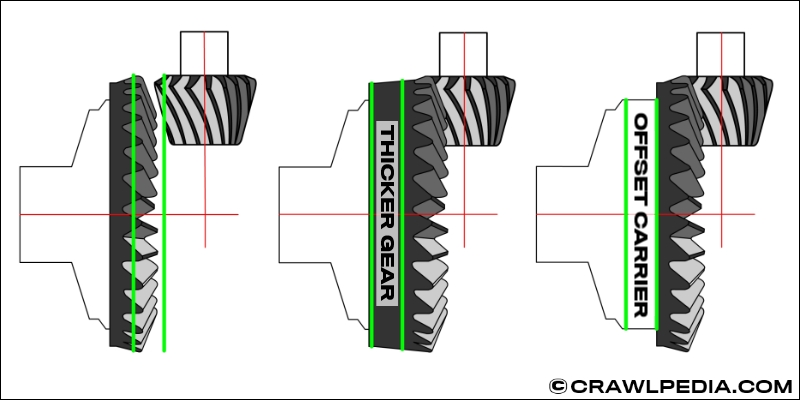

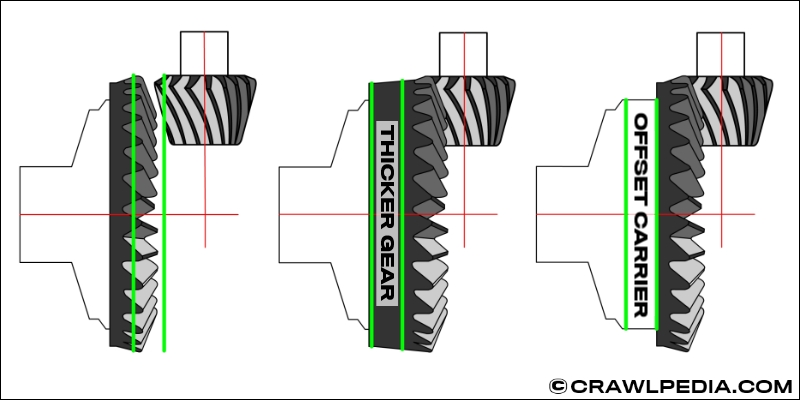

The gap between the ring gear and pinion gear is corrected in two ways: The first way is to make the ring gear thicker and the other is to use an offset differential carrier that moves the ring gear closer to the pinion. While it would be nice to avoid changing the carrier and use thicker gears for all ratios, there is a point at which the rotating mass of the additional material begins to negatively affect performance. This is why many axle manufacturers use two different carriers for high and low gear ratios.

What is a Carrier Break?

Axles that are designed for use with a large range of gear ratios often have two different differential carriers, one for lower gears and one for higher gears. The point at which the axle switches from one carrier to the other is called the carrier break. For example, the Dana 60 axle has a 4.10/4.56 carrier break that requires one carrier for 4.10 and numerically lower gears and another carrier for 4.56 and higher gears.

When changing gears in an axle, it is important to determine if the axle has a carrier break and if so, which carrier it has installed. If the axle does not have a carrier break, then any aftermarket gears will fit just fine. If the axle does use a carrier break, then the first thing that needs to be checked is if the new gear ratio is on the same side of the carrier break as the existing gears or if they will be "jumping the break".

For gear changes where the gear ratio crosses the carrier break, the installation will require the use of the other differential carrier. Luckily, aftermarket differential and locker manufacturers are aware of this and almost always offer models for both lower and higher carriers.

Some aftermarket gear manufacturers also offer ring gear spacers and thick gears that are designed to jump a carrier break without the need for changing the carrier. These gears are not available for all applications or all gear ratios, however, whenever possible, they are a great option.

How to Select The Right Gears and Carrier

Step 1: Determine If Your Axle Has A Carrier Break

Find your axle in the table below to see if it has a carrier break. If so, then you need to check and see if your current gear ratio is on the low carrier or the high carrier. If not, then all gear ratios will fit on the stock carrier and you can't go wrong.

Step 2: Find Your Existing Gear Ratio

If you don't know your existing gear ratio, you can use our Gear Ratio Calculator to figure that out.

Step 3: Select Your New Gear Ratio

Using our Gear Ratio Finder and Engine RPM Calculator, select the appropriate gear ratio for your application.

Step 4: Check If The New Gears Jump the Carrier Break

If your new gear ratio is within the same carrier range as the stock gears, then standard gears will work fine. If your current gear ratio is on the low carrier and your new gears are on the high carrier, then you will need to change the carrier, use a ring gear spacer, or find thick gears. If your existing gears are on the high carrier, and your new gears require the lower carrier, then you will need to change to the lower carrier.

| Current Ratio | New Ratio | Installation Options |

|

| Lower Carrier | Lower Carrier | Standard Gears on Lower Carrier |

|

| Lower Carrier | Higher Carrier | Standard Gears on Lower Carrier with Ring Gear Spacer

Standard Gears on Higher Carrier

Thick Gears on Lower Carrier |

|

| Higher Carrier | Lower Carrier | Standard Gears on Lower Carrier |

|

| Higher Carrier | Higher Carrier | Standard Gears on Higher Carrier |

|

Tip: Aftermarket Carriers, Limited Slips, and Lockers

Most aftermarket differential manufacturers offer both carriers so if you plan on upgrading your differential with your new gears, make sure that you order the correct one so that you can run standard gears and avoid needing thick gears or spacers.

Popular Axle Carrier Breaks

This thick gear and carrier break guide is ©Copyright Crawlpedia.com - Please provide a link back to this page when copying.

Data is accurate to the best of our knowledge and is offered as-is with no guarantee.

More Gear and Axle Guides:

Differential Locker Comparison - A detailed comparison of popular differentials and lockers.

Ring and Pinion Setup Specs - Ring and pinion gear setup specifications for popular axles.

Ring and Pinion Gear Tooth Patterns - Gear tooth pattern setup and adjustement instructions.

Gear Ratio Finder - Find the ideal axle gear ratio for your new larger or smaller tires.

Gear Ratio Calculator - Calculate the gear ratio of gears based on their tooth count.

Ring and Pinion Ratio Variations - An explanation of why some ring and pinion gear ratios vary.

Filthy Motorsports

High performance off-road racing parts and professional shock tuning. Learn more at

FilthyMotorsports.com

Shock Service, LLC

Professional shock tuning and rebuilding services for King and ADS shocks. Learn more at

ShockService.com

Polar Cryogenics

Cryogenic treatment improves strength and longevity of gears, axle, and brakes. Learn more at

PolarCryogenics.com

Crown Race Gears

Race-spec ring and pinion gears for desert racing, rock bouncing, and rock crawling. Learn more at

RaceGears.com